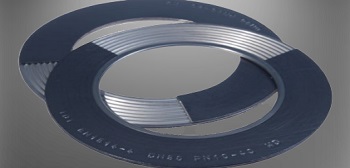

Corrugated seals consist of a corrugated body with a graphite cover on both sides. The system allows for a very small diffusion cross-section, and the material is strongly compressed in this area. The corrugated beam can be coated with graphite completely [WD 10/WD 20] or only partially [WD 12/WD 24], which then ensures increased safety against blowout, higher stability and controllability. Corrugated seals show high tightness even with slight surface compression [δVU 0.01 = 22 MPa]. We supply seals in the shape of a circular ring, oval or as a frame. Bridges [at least 8 mm wide], clips and holes for screws can be made in advance. Special welding technologies ensure high weld quality for large seals and prevent corrosion for stainless steel beams. Small sealing beams are made of one piece.

Applications: Established sealing system for the chemical and petrochemical sector, in conventional power and nuclear power stations, for steam generation and in device construction, especially wherever high temperatures and pressures have to be managed safely. Gaskets for pipeline flanges, device and container flanges, for existing and new plants. Can be covered with graphite or PTFE as non-metallic material. For higher temperatures with mica layer and base body made from 1.4828, e.g. for use in exhaust pipes. Flexible or warped flange surfaces which have to seal safely atlow surface pressure.

Corrugated metal gaskets offer:

| MATERIAL BODY | MATERIAL COVER | TEMPERATURE | PRESSURE | ATESTS | DATA SHEET | |

| WD10 | 1.4671 |

GRAFIT | -200°C to 550°C | 160 |

TA Luft/BAM O+E+P/Fire Safe Test/Blow out/DVGW | PDF |

| PTFE | -200°C to 250°C | TA Luft/BAM E+P/Fire Safe Test/Blow out/DVGW | ||||

| WD12 | GRAFIT | -200°C to 550°C | 160 |

TA Luft/BAM O+E+P/Fire Safe Test/Blow out | PDF |

|

| PTFE | -200°C to 250°C | TA Luft/BAM E+P/Fire Safe Test/Blow out | ||||

| WD20 |

1.4671 |

GRAFIT | -200°C to 550°C | 160 |

TA Luft/BAM O+E+P/Fire Safe Test | PDF |

| PTFE | -200°C to 250°C | TA Luft/BAM E+P/Fire Safe Test | ||||

| WD24 |

GRAFIT | -200°C to 550°C | 160 |

TA Luft/BAM O+E+P/Fire Safe Test | PDF |

|

| PTFE | -200°C to 250°C | TA Luft/BAM E+P/Fire Safe Test |